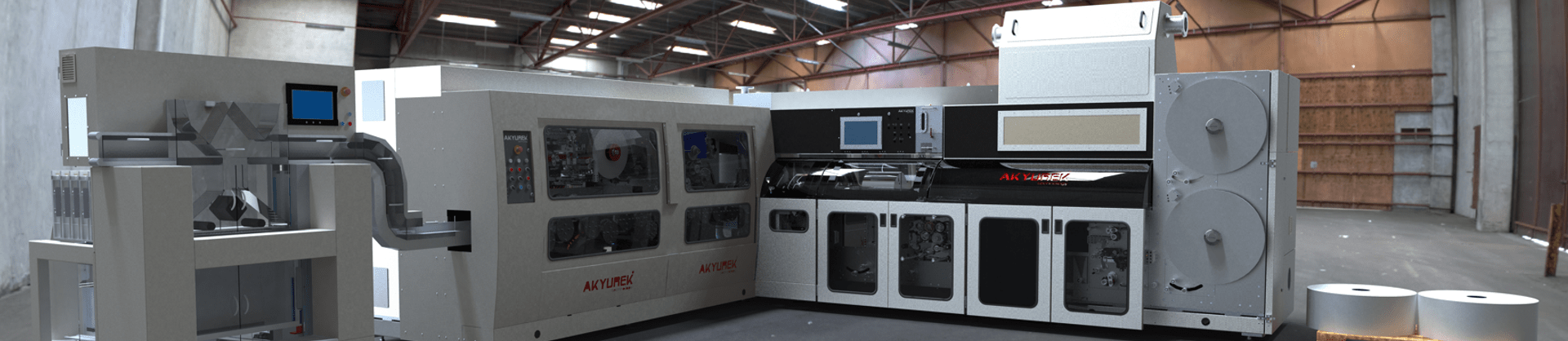

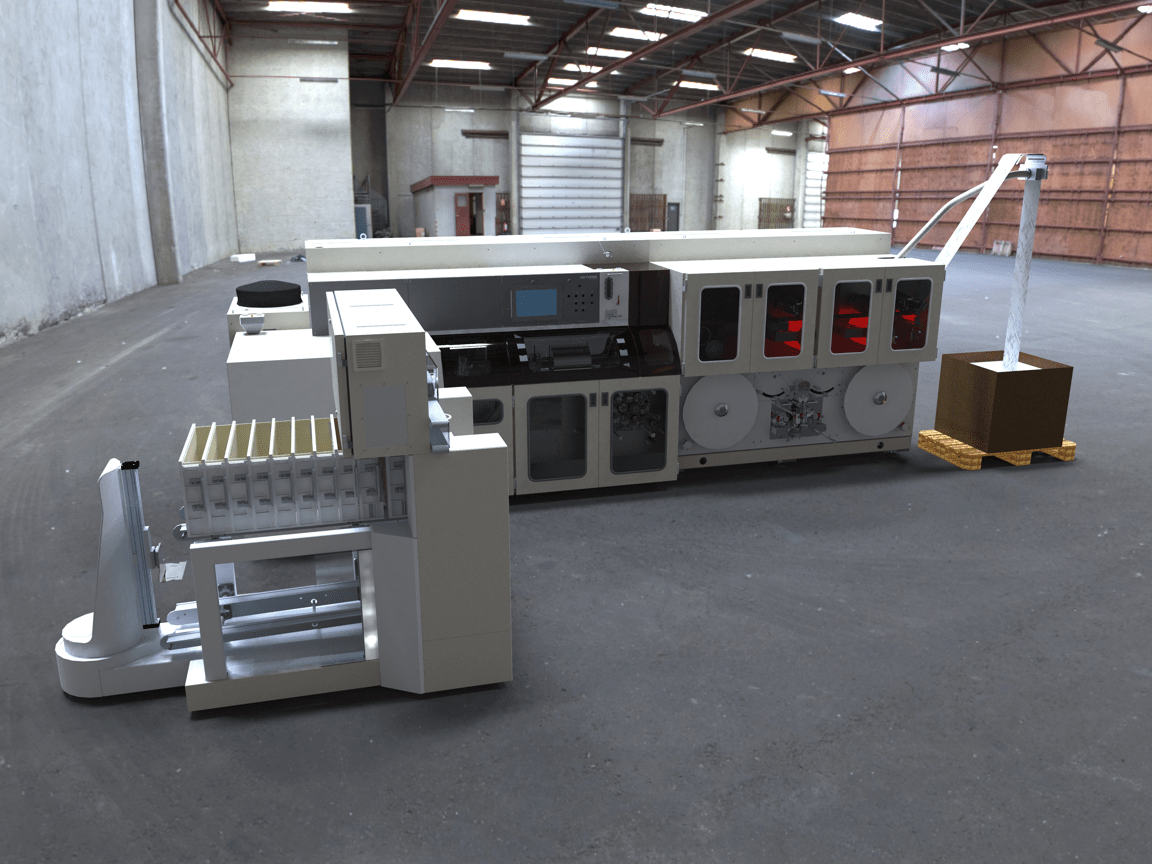

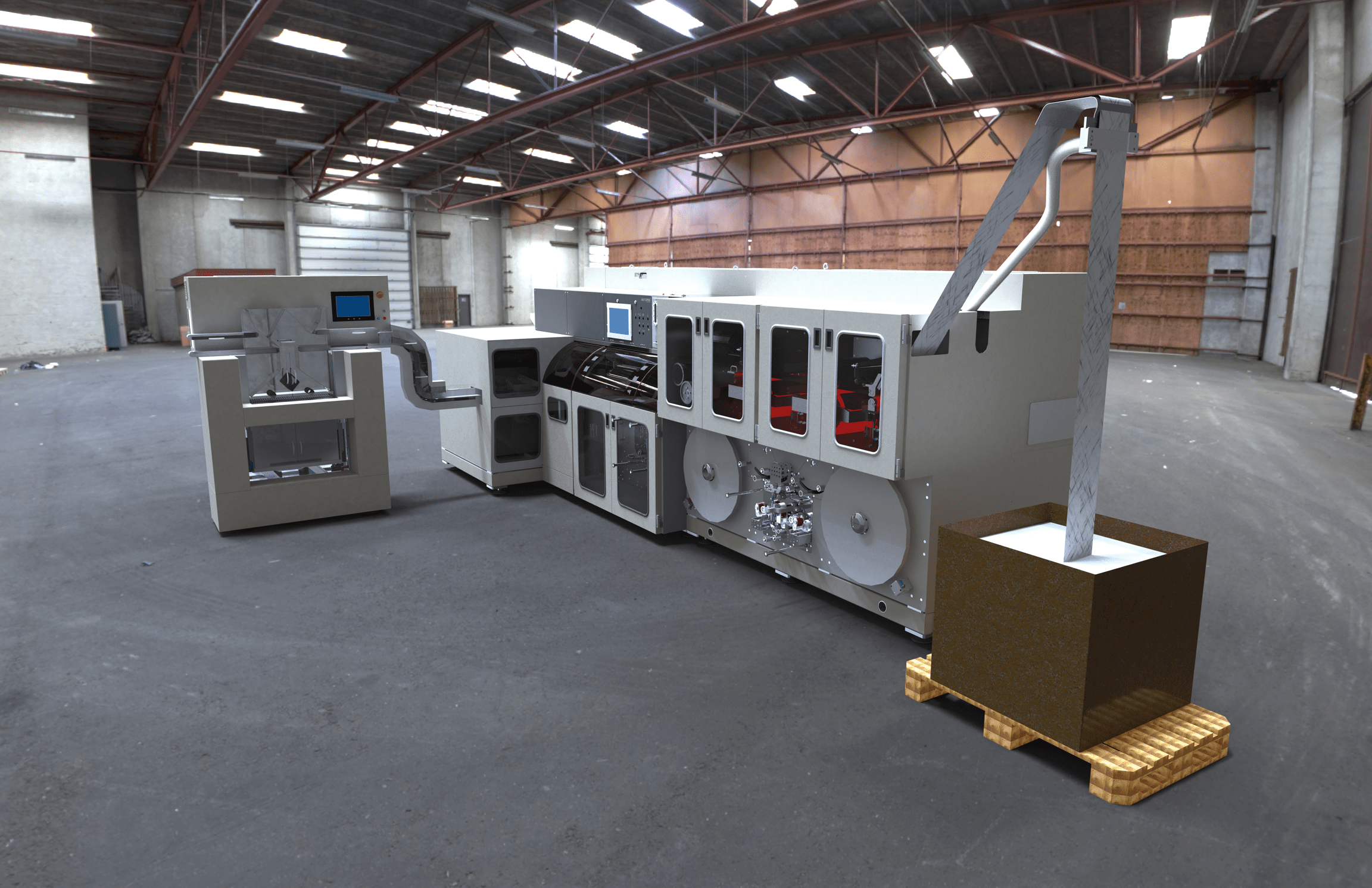

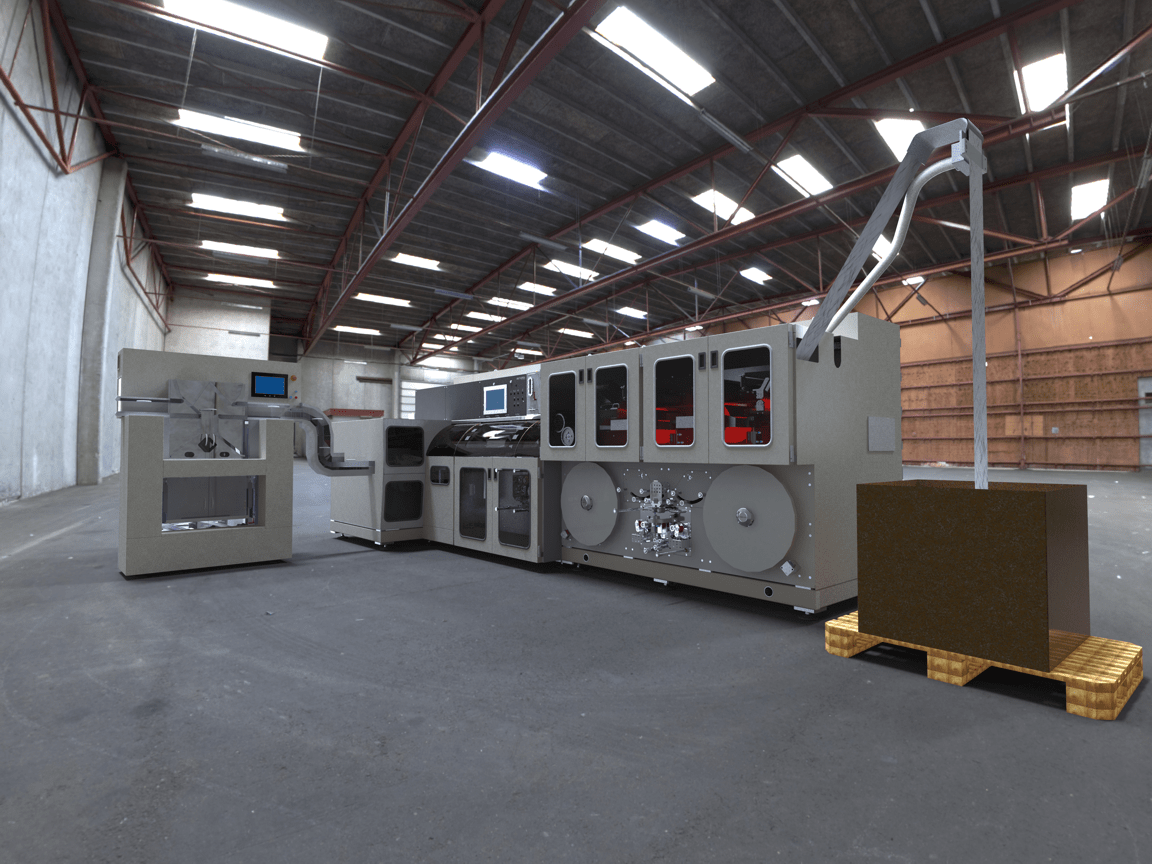

FILTER ROD MAKER & TRAY LOADER

SMD Solutions

As Akyurek Technology we are offering you our new hi-tech filter rod maker machine along with filter tray loader.

As Akyurek Technology we are offering you our new hi-tech filter rod maker machine along with filter tray loader. Akyurek Filter Rod Maker is designed as modular for being user friendly, low maintenance and spare part cost. It is the best solution for filter manufacturing for cigarette and cigarette tubes.

Complete line for the production of filter rods monoacetate kind. The line has the following modules.

- Acetate elaboration module

- Filter rod maker

- Filter control and transfer device

- Filter tray loader

Dimensions in ground: 6000x4000 mm

Electrical Input: 400V three-phase L1, L2, L3, N, PE

Flow Air: 150 m³/h

Sound Level: 80 dB(A) (measured at 500 mm from the protections)

Colour of the machine: RAL 9001, RAL 2009 danger zones

Manual and display language: Spanish, English, Turkish

Pressurized air supply: 6 bar 450 l/min Ouality of pressurized air suplly.

- Residual dust: 0.1 um / 0.1 mg/m3

- Residual water: PSD 3 / 0.1 mg/m3

- Residual oil: 0.1 mg/m3

- Kit of tools and tools needed to operate the machine included.

- Calibration tools included

- Laser diameter control and automatic adjust

- Servo control Omron Sysmac

- 2 core NJ5 CPU 8 Axex Control

- 10” Screen NA Sysmac

- EtherCat, EtherNETIP

- Servo control Omron Sysmac

- 4 core NX7 CPU 128 Axex Control

- 15” Ekran NA Sysmac

- EtherCAT, EtherNETIP

- Working speed with monoacetate up to 500 m / minute

- Frequency inverters-controlled blowers

- High pressure precise acetine metring system

- DC static discharger

- Full servo control for the drums

- Central automatic pneumatic system

- Cutting of the filter rod in single position

- Steel filter cutting Blades with brushless sharpeners with automatic advance system

- Two bobbin unwinders servo driven

- Ultrasonic detection of the factory splice on the bobbins’ blowers

- Removable centralized lubrication system with high efficient chiller cooling.

- Ich circuit of the lubricat on with separate flow control

- Double fixed bobbin holder with direct servo motor and fine position adjustment

- Splice in bobbins detector

- Double scrapper.

- High speed paper splice.

- Hot glue seem side glue system

- PVA and hot glue inter system

- Two chillers for separate temperature

- Automatic speed control

- Product on collect on and product on reports

- Main screen and operator panel.

- Servo-driven garniture tape.

- Garniture belt 22x3540

- Tension of the belt dynamic cont

- DC static discharge

- Wet and dry filter sample reject

- Start stop reject drum

- Universal connection to the tray loader

- Full automatic trey loader

- Main screen and operator panel.

- Prepared to the standard word filter tray

- Prepared to load filters into the standard carton box

- Automatic aligner with dynamic force control 10 empty trays automatic buffer 12 full trays automatic buffer

- Automatic lift up system (full adjustable exit)

WHY AKYUREK?

- High Quality Raw Material

- Long Lasting Usage

- Customised Dimensions

- Long Lasting Usage

- Customised Dimensions

- Finest Craftmanship

- Reasonable Price

- 7/24 After Sales Service

- Spare Parts Accessibility

- Reasonable Price

- 7/24 After Sales Service

- Spare Parts Accessibility